ATI seeks to be the world's best specialty metals company by providing our customers with unmatched product breadth, unparalleled technical depth and unsurpassed manufacturing capabilities that solve their most difficult challenges.

unparalleled technical depth and unsurpassed manufacturing capabilities that solve their most difficult challenges.

We are one of the largest and most diversified specialty metals producers in the world with employees located world-wide. We offer global markets a wide range of specialty metals solutions to markets and customers located throughout the world.

Our major markets are aerospace and defense, oil and gas/chemical process industry, electrical energy, medical, automotive, food equipment and appliance, machine and cutting tools, and construction and mining.

ATI operates in the following three business segments.

ATI operates in the following three business segments.

Our High Performance Metals segment produces, converts and distributes a wide range of high performance alloys, including nickel- and cobalt-based alloys and superalloys, titanium and titanium-based alloys, exotic metals such as zirconium, hafnium, niobium, nickel-titanium, and their related alloys, and other specialty alloys, primarily in long product forms such as ingot, billet, bar, shapes and rectangles, rod, wire, seamless tube, and castings. We also produce nickel-based alloys and superalloys, titanium alloys, and specialty metal powders, and semi-finished near-net-shape products from these advanced powder alloys. Through the acquisition of ATI Ladish, we produce precision forgings, castings and machined parts. We are integrated from raw materials (sponge) to melt, remelt, finish processing, forging, investment casting, and machining in our titanium and titanium alloys, and zirconium and hafnium alloys products. The major end markets served by our High Performance Metals segment are aerospace and defense, oil and gas, chemical process industry, electrical energy, and medical. Most of the products in our High Performance Metals segment are sold directly to end-use customers. A significant portion of our High Performance Metals segment products are sold under multi-year agreements.

Our Flat-Rolled Products segment produces, converts and distributes stainless steel, nickel-based alloys and superalloys, titanium and titanium-based alloys and specialty alloys in a variety of product forms, including plate, sheet, engineered strip, and Precision Rolled Strip® products, as well as grain-oriented electrical steel sheet. The major end markets for our flat-rolled products are oil and gas, chemical process industry, electrical energy, automotive, food equipment and appliances, construction and mining, aerospace and defense, and electronics, communication equipment and computers.

Our Flat-Rolled Products segment produces, converts and distributes stainless steel, nickel-based alloys and superalloys, titanium and titanium-based alloys and specialty alloys in a variety of product forms, including plate, sheet, engineered strip, and Precision Rolled Strip® products, as well as grain-oriented electrical steel sheet. The major end markets for our flat-rolled products are oil and gas, chemical process industry, electrical energy, automotive, food equipment and appliances, construction and mining, aerospace and defense, and electronics, communication equipment and computers.

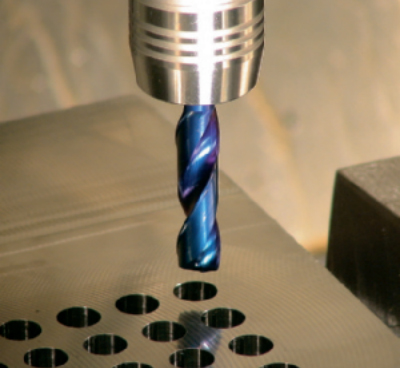

The principal business of our Engineered Products segment includes the production of tungsten powder, tungsten heavy alloys, tungsten carbide materials, and tungsten carbide cutting tools. We are integrated from the raw materials (ammonium paratungstate (APT)) to the manufacture of our tungsten-based products. The segment also produces carbon alloy steel impression die forgings, and large grey and ductile iron castings, and provides precision metals processing services. We produce a line of sintered tungsten carbide products that approach diamond hardness for industrial markets including automotive, oil and gas, chemical process industry, machine and cutting tools, aerospace, construction and mining, and other markets requiring tools with extra hardness. Technical developments related to ceramics, coatings and other disciplines are incorporated in these products. We also produce tungsten and tungsten carbide powders. We forge carbon alloy steels into finished forms that are used primarily in the transportation and construction equipment markets. We also cast grey and ductile iron metals used in the transportation, wind power generation and automotive markets. We have precision metals processing capabilities that enable us to provide process services for most high-value metals from ingots to finished product forms. Such services include grinding, polishing, blasting, cutting, flattening, and ultrasonic testing.